A Safer Tool for Operations: 3D Scans for Technical Tasks

“Our number one goal? Easy. Eliminate hazardous risk in the facility.”

When asked about the top priority for their operations, a plant manager gave that response.

“If we can eliminate risk on site, we’re winning with our guys. And typically our technical processes are the ones that have the most risk involved.”

Every day, operators across energy, chemical, and manufacturing sites perform procedures that demand precision and carry risk.

From hydrogen purging to high-voltage switching, even one misstep can have serious consequences.

Plant managers know the importance of using their resources, culture, and systems to create the safest environment possible in the nation’s most dangerous industries.

Legacy Methods Don’t Cut It

When it comes to keeping employees safe, the best methods are the most critical to keeping workers in the clear.

Legacy training methods have been helpful in the past, yet they can also be the bare minimum and a barrier to better safety.

Traditional instructions (like paper SOPs, classroom walkthroughs, or “follow Joe, he’s been here 20 years”) are no longer enough to protect teams, and do a poor job of truly preserving critical knowledge.

Specific to safety, the best organizations are always looking for ways to change the way people work, isolate people from a hazard, or even physically eliminate the possibility of risk.

Safety professionals often use a framework called the Hierarchy of Controls to prioritize the most effective ways to reduce risk – putting on personal protective equipment all the way up to physically removing hazards.

Those traditional methods are important for giving teams context for how technical tasks have been executed in the past.

But they all lack spatial context.

A diagram of a hydrogen purge or a checklist for a high-voltage switch may have the “what” that needs to be done, but significantly lacks visual context. Costly delays, unsure execution, and unsafe improvisation all expose a technician and facility to risk.

Workers need a better tool for these technical tasks.

In talking with many of our users, we’ve found that 3D visualization aligns squarely with engineering and administrative controls, yet is also capable of delivering at the elimination level. Digital scans are able to isolate people from hazards and change how work gets done, long before PPE is even needed.

The Advantage of 3D Scans

Why are we suggesting utilizing 3D scans for technical tasks?

A Digital Transformation leader at a leading utility company answered this question in relation to how his team is using 3D scans across their power generation fleet.

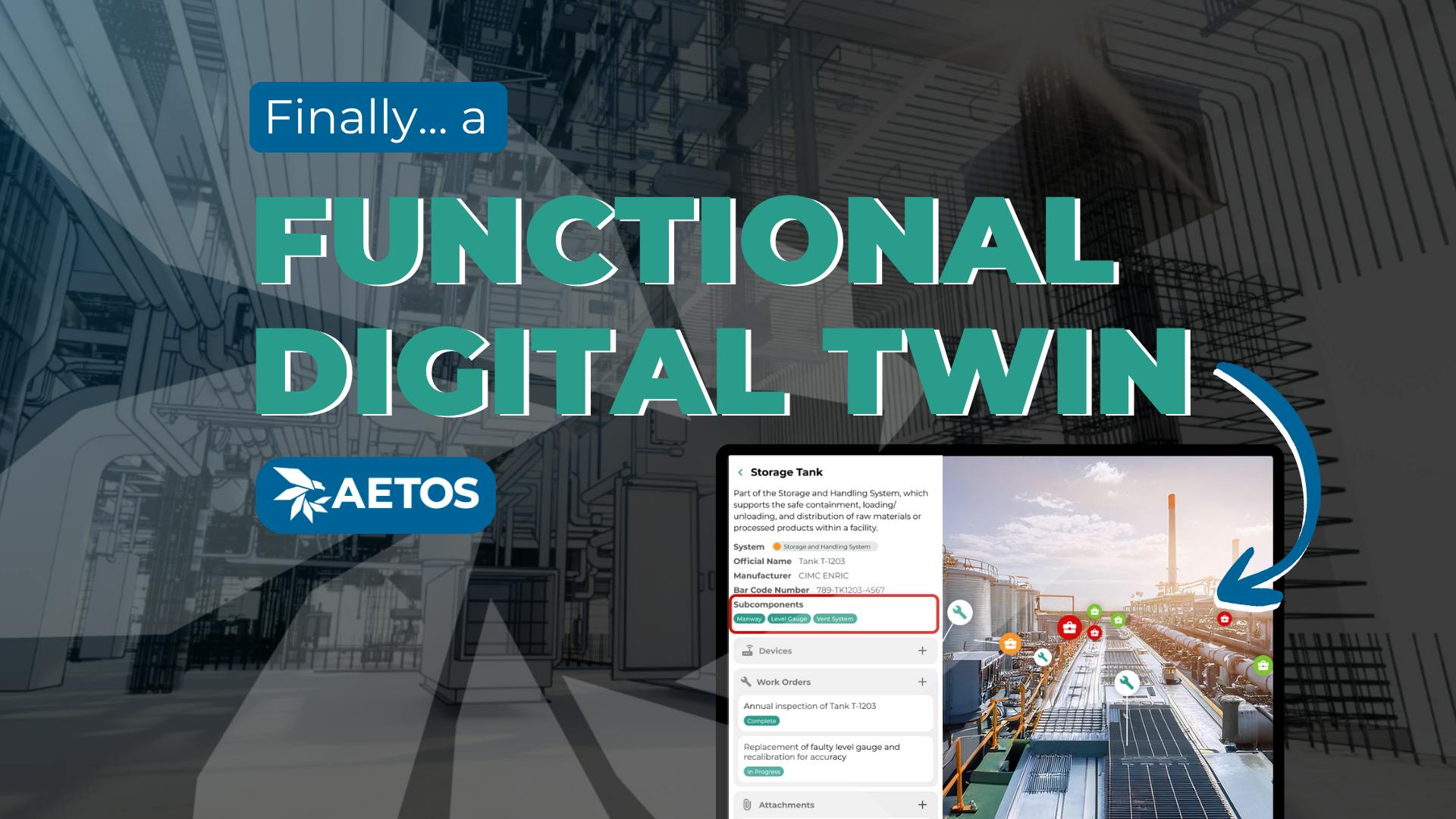

“We use the technology to access information about equipment for operations and maintenance. Now, we’re using computer systems to find accurate information much more efficiently through the Aetos models.”

What he’s describing is the shift from static information to situational awareness.

3D scanning changes everything.

This solution is letting teams layer critical knowledge on top of high-resolution digital twins; teams can train on procedures step-by-step before even setting foot onsite.

Embedding visual SOPs and training courses on a digital representation of their actual facility is the modern way for on-the-job training, without the hazards, scheduling conflicts, noisy distractions, unsafe environments, or production downtime.

3D scans truly are a loaded advantage for organizations looking to take their technical tasks to the next level.

Best practices, in-depth training, and visual guidance are all readily available at a technician’s fingertips. Your facility – and all its O&M systems and processes – is now in your pocket.

When you combine visual SOPs with contextual training, you turn procedural compliance into operational confidence

Reducing Risks Before They Happen

Visualizing technical tasks eliminates many of the most common risk factors in high-hazard environments.

New and current employees can learn and understand areas virtually instead of climbing a ladder or getting in a cab.

Supervisors and safety leaders can further explain what the learner needs to know with visual context.

Reducing these risks also improves outcomes:

- - Fewer hazardous exposures as digital rehearsal means fewer truck rolls, climbs, or confined entries.

- - Faster knowledge transfer by leveraging a comprehensive learning platform that speaks to all 4 learning styles.

- - Better retention and compliance due to teams remembering procedures longer and performing them more accurately.

- - Reduced incident rates as employees understand why and where each action occurs.

In industries where safety and uptime are inseparable, those gains matter.

That’s why organizations are turning to 3D technical training: a safer, more immersive learning environment where employees can visualize procedures, practice steps, and access best practices and professional support.

See the Space Before Setting Foot Onsite

The ability to preview a facility virtually before ever stepping foot onsite changes how teams prepare, plan, and protect themselves (and significantly reduces truck rolls or ladder climbs).

A technician can now familiarize themselves with valves, lines, and hazard zones in a true-to-life 3D environment. Schematics and photos just don’t accomplish what a 3D scan can.

Likewise, supervisors can verify that each worker understands the sequence, space, and safety boundaries of the task before the first wrench turns.

It all points to a new level of situational awareness: teams can prepare and arrive onsite more informed and more confident.

Bridging the Gap Between Legacy and Modern Systems

Change doesn’t – and won’t – happen overnight. Some training programs have taken decades to build. Companies have every right to be cautious about adopting tools and technologies.

However, modernization does not mean replacement of those legacy systems.

We know introducing a new solution might disrupt what already works.

That’s why our approach starts with respect for your existing systems and people.

Because of this, Aetos aims to bridge that gap and be your partner on your digital transformation journey.

We work alongside your existing systems (ie SOPs, CMMS, and/or LMS) and bring them to life. Aetos proudly integrates with most of the legacy systems in place. Instead of forcing a new process, we aim to help your current one be smarter and more connected.

Our approach is practical: start small, prove value, and scale with your operations.

Visual tools strengthen your safety culture. We aim to help you engineer out exposure and change how work is done – two of the highest forms of control in the safety hierarchy.

Your safest workers are your most informed workers. And when it comes to complex, technical tasks, giving the most information (and the most readily available information) is the safest way to operate.

Eliminate hazardous risks. Train with site-specific context. Give your current teams – and your next generation of workers – the safest tool for today and tomorrow.